In 2021, Mr. Liu Sihan design of PET (POLYESTER)hexagonal net machine after years of improvement, the ultimate speed of the equipment is an amazing 20 times/minute, the overall speed is far more than 10 times/minute weaving speed abroad.Up to now, Mr. Liu Sihan is still trying to design different equipment in the hexagonal network machinery industry. And set up a research and development company in the provincial capital Shijiazhuang (Hebei Hengtuo Machinery Equipment Co., LTD.), is committed to the research and development and improvement of wire mesh machinery.

At the end of the 1980s, located in Shandong, China, a Japanese investment hexagonal network factory, commissioned Mingyang machinery (the original Li Qingu district speed over parts factory), accessories processing and old equipment renovation.

Mr. Liu Zhansheng, the factory director at that time, was inspired by The Japanese equipment, and developed and transformed a Chinese is twisting small hexagonal net machine. Since then opened the Ming Yang machinery hexagonal net machinery production journey.

At the end of 1990s, Mr. Liu Zhansheng retired to the second line, the factory was handed over to his son Mr. Liu Yongqiang, and in 2005 renamed dingzhou Mingyang Machinery Factory, focusing on the equipment production of hexagonal mesh machine. Whether positive or positive, whether mesh size can be customized according to customer requirements.

In 2007, a company in Taiwan found Mingyang machinery, hope to cooperate with a can be used to weave PET hexagonal network equipment, but because the PET (POLYESTER) hexagonal network in the domestic market is small, recognition is very low, and due to the cost of equipment research and development, only a version of the basic sketch, and did not carry out actual production.

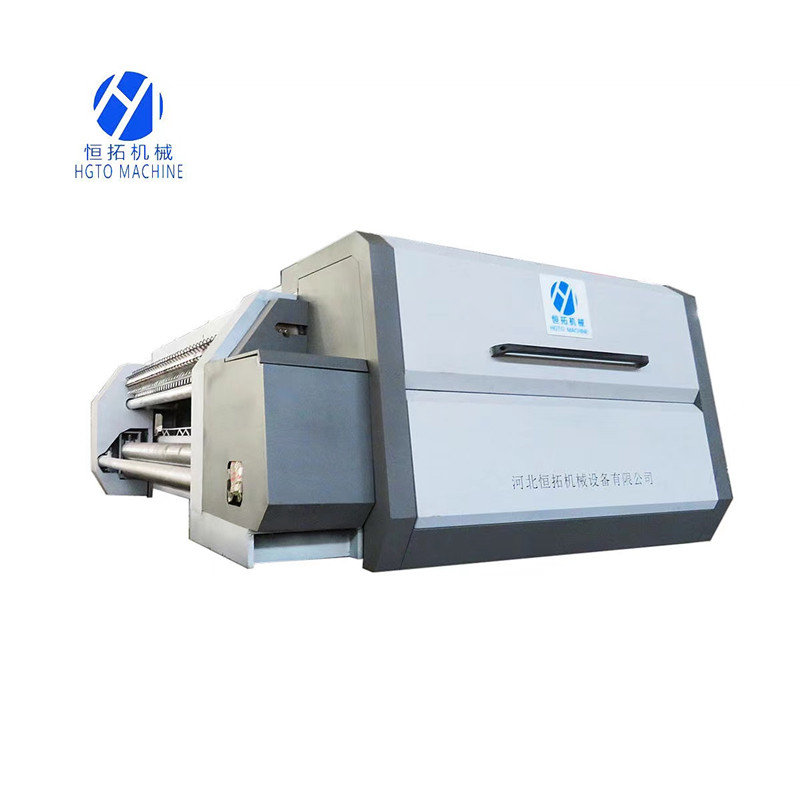

In 2010, is twist small hexagonal network machine market tends to saturation, Mingyang machinery began a research and development: Horizontal stone cage net machine, horizontal stone cage net machine design knitting diameter, between twist small hexagonal net machine and heavy stone cage net machine, twist small hexagonal net machine can not weave more than 200 wire larger wire diameter, and this 200-300 wire diameter for heavy stone cage net machine weaving cost is too high.So the horizontal stone cage net machine developed independently by Mingyang Machinery emerged at the historic moment.The reason why there is no vertical structure of the traditional stone cage net machine, is due to The persistence of Mr. Liu Yongqiang for the twisting spring equipment, according to Mr. Liu Yongqiang's idea of the year to replace the form of the winding frame spring equipment, horizontal structural design is a good choice.Domestic has been the purchase of mingyang machinery horizontal gabion net machine for PET hexagonal net experiment, has also been mentioned, this equipment really like a PET hexagonal net machine tailored.As everyone knows, the horizontal stone cage net machine was liu Yongqiang was inspired by Taiwan customers, a preliminary idea for this type of equipment.

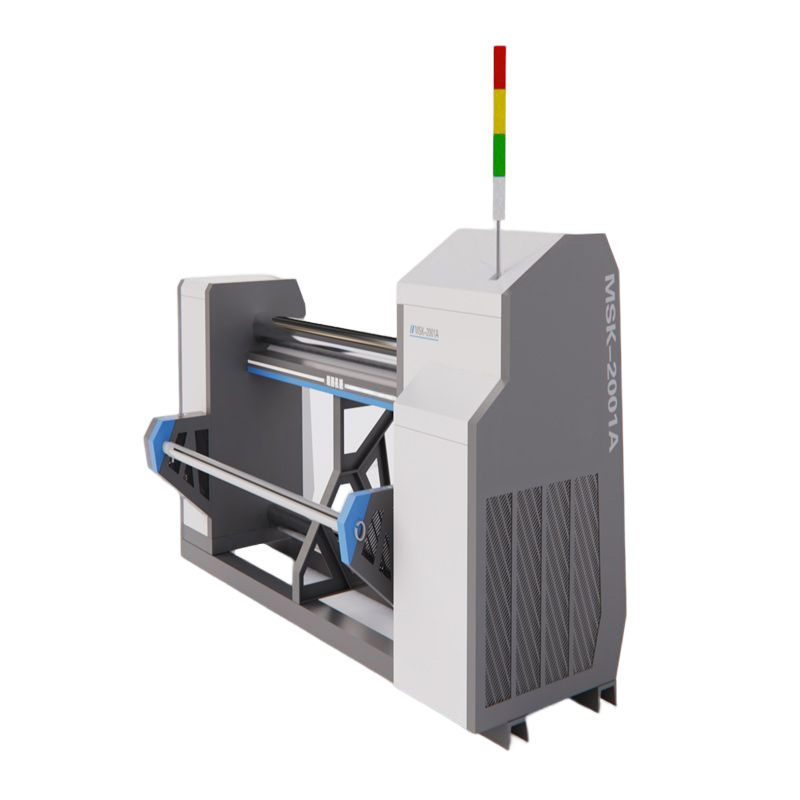

In 2016, Mr. Liu Yongqiang's son, Mr. Liu Sihan, graduated from the department of mechanical Engineering. The young man from a technical background has his own unique ideas and backbone. He gives enough respect to the foreign original, disdants to imitate others, and independently designed a winding group with completely different ideas from Japanese equipment.The design of winding group is not only suitable for PET silk weaving, but also includes iron wire and steel wire weaving.Foreign equipment is screen factory production and use, installation is very inconvenient, need personnel to install.Mr. Liu Sihan directly adopts modular design and divides the winding group into different winding modules. Each module has its own independent power unit, which can be used independently or splice according to the needs of the mesh.Mr. Liu Sihan believes that to do mechanical equipment, we should have the idea of "lazy". We should not do what equipment can do, and we should not leave the problems we can solve to customers. What excellent practitioners of mechanical industry should do is to raise people to be "lazy". Let the equipment take care of everything!So Mr. Liu Sihan POLYESTER hexagonal net machine directly bold to cancel the design of the cylinder, do not need to prepare the user air compressor.Even in his latest design, the use of bolts was reduced by 90%, because he believed that the use of a large number of bolts had unstable factors, such as vibration, loosening and falling of bolts, which would affect the performance of the equipment. Moreover, it took time and effort for workers to screw bolts, and customers needed to regularly check the use of a large number of bolts.

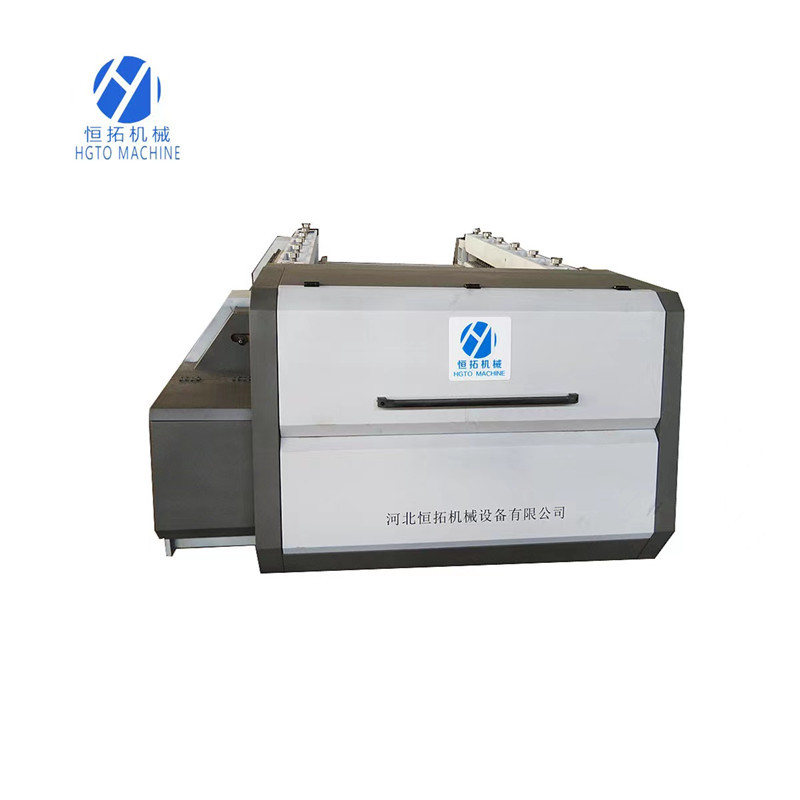

In 2021, Mr. Liu Sihan design of PET (POLYESTER)hexagonal net machine after years of improvement, the ultimate speed of the equipment is an amazing 20 times/minute, the overall speed is far more than 10 times/minute weaving speed abroad.Up to now, Mr. Liu Sihan is still trying to design different equipment in the hexagonal network machinery industry. And set up a research and development company in the provincial capital Shijiazhuang (Hebei Hengtuo Machinery Equipment Co., LTD.), is committed to the research and development and improvement of wire mesh machinery.

At the end of the 1980s, located in Shandong, China, a Japanese investment hexagonal network factory, commissioned Mingyang machinery (the original Li Qingu district speed over parts factory), accessories processing and old equipment renovation.

Mr. Liu Zhansheng, the factory director at that time, was inspired by The Japanese equipment, and developed and transformed a Chinese is twisting small hexagonal net machine. Since then opened the Ming Yang machinery hexagonal net machinery production journey.