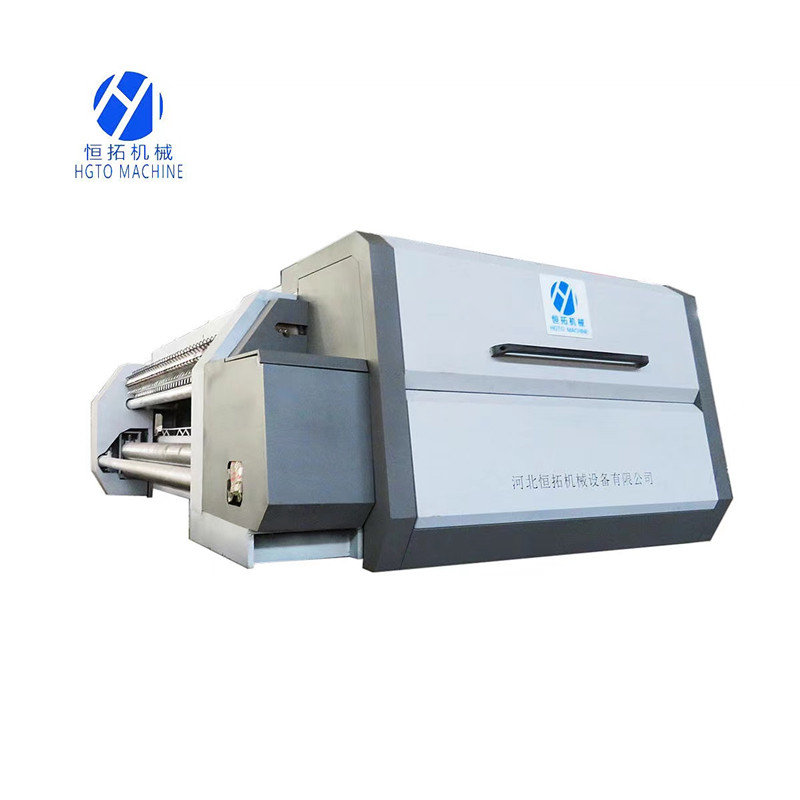

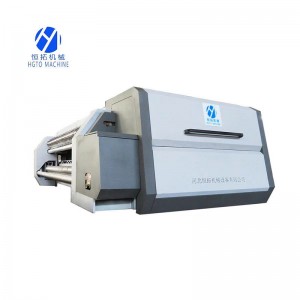

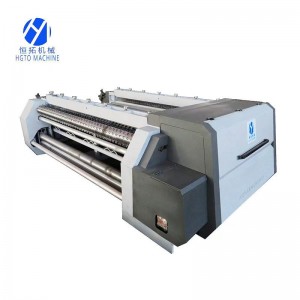

Polyester Material Gabion Wire Mesh Weaving Machine

Description

Gabion basket machine have smooth operation, low noise and high efficiency characteristics. Gabion mesh machine, also called horizontal hexagonal wire mesh machine or gabion basket machine, Stone cage machine, Gabion box machine, is to produce the hexagonal wire mesh for reinforcement stone box use. This kind of stone cage net equipment is not the same as the metal cage net equipment, which is specialized in the production of PET material stone cage net, with amazing tensile strength. It's safe to assume that decades of exposure in the wild don't change its physical properties at all.

Corrosion resistance is a very important factor for both land and underwater applications. PET is in nature resistant to most chemicals, and there is no need for any anti-corrosive treatment. PET monofilament has obvious advantage over steel wire in this regard. To prevent from corrosion, the traditional steel wire either has galvanized coating or PVC coating, however, both are only temporarily corrosion resistant. A wide variety of plastic coating or galvanized coating for wires have been utilized but none of these have proven completely satisfactory.

|

characteristic |

PET hexagonal wire mesh |

Normal iron wire hexagonal mesh |

|

Unit weight (specific gravity) |

Light (small) |

Heavy (large) |

|

strength |

High, consistent |

High, decreasing year by year |

|

elongation |

low |

low |

|

heat stability |

high temperature resistance |

Degraded year by year |

|

anti-aging |

Weathering resistance |

|

|

acid-base resistance property |

acid and alkali resistant |

perishable |

|

hygroscopicity |

Not hygroscopic |

Easy to moisture absorption |

|

Rust situation |

Never rust |

Easy to rust |

|

electrical conductivity |

non-conducting |

Easy conductive |

|

service time |

long |

short |

|

use-cost |

low |

tall |

Advantages of HGTO PET Gabion Wire Mesh Machine

1. Combine the market demand, bring forth the new through the old and improve the production efficiency.

2. Horizontal structure is adopted to make the machine run more smoothly.

3. The volume is reduced, the floor area is reduced, the electricity consumption is greatly reduced, and the cost is reduced in many aspects.

4. The operation is more simple and the long-term labor cost is greatly reduced.

Specification of Hexagonal Wire Mesh Making Machine

|

Main Machine Specification |

|||||

|

Mesh Size(mm) |

Mesh Width |

Wire Diameter |

Number of Twists |

Motor |

Weight |

|

60*80 |

MAX3700mm |

1.3-3.5mm |

3 |

7.5kw |

5.5t |

|

80*100 |

|||||

|

100*120 |

|||||

|

remark |

Specific mesh size can be customized according to customer requirements | ||||

Company Profile

Hebei hengtuo machinery equipment CO., LTD is a integrates research and development, production and sales as one of the manufacturers. Since its inception, we insist on the principle of "Quality to service, Customers are first".

Our wire mesh machine have always been in the industry leading level, the main products are Hexagonal wire mesh machine, Straight and reverse twisted hexagonal wire mesh machine, Gabion wire mesh machine, Tree root transplant wire mesh machine, Barbed wire mesh machine, Chain link fence machine, weld wire mesh machine, nail making machine and so on.

All departments work together to make sure all the machines and products good quality and supply good after-sales service. Due to the joint efforts of all staff, our products are exported to many countries, and gain good reputation and long cooperation from domestic and overseas.

After Sales Service

1. Within guarantee time, if any components are broken under normal condition, we can change for free.

2. Complete installation instructions, circuit diagram, manual operations and machine layout.

3. Guarantee time: one year since machine was at buyer's factory but within 18 months against B/L date.

4. We can send our best technician to buyer's factory for installation, debugging and training.

5. Timely reply for your machine questions, 24 hours support service.